PWM devices can be used to change a 5 forward/3 reverse set speed motor, like the NV Series motor, into a variable speed trolling motor. This will lead to increased efficiency leading to longer battery life and allowing you to spend more time on the water using your motor. Please continue reading to learn more on this subject!

-

How does a PWM device Work?

-

What do you need to buy to set up a PWM?

-

What features do I need and how to choose?

-

How to Wire?

-

How to store/protect your PWM device?

-

How to install a PWM device?

-

How to turn on a PWM device?

-

How to change between forward and reverse?

1. How does the PWM device work?

Trolling motors today receive power in two popular ways, DC and PWM. Newport Trolling Motors are DC motors or Direct Current. DC creates a continuous stream of power and is pulled by the motor at each speed. All of our motors have 5 speeds in forward and 3 speeds in reverse, which pull different amounts of power at each speed.

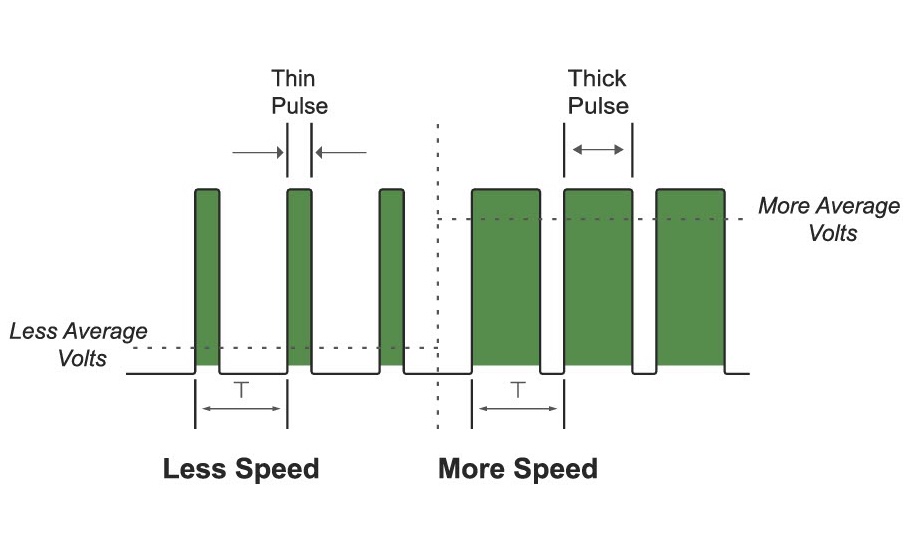

PWM or Pulse Width Modulation is a method that sends current in pulses by turning the power on and off rapidly. A dimmer switch on a light works like a PWM. If you turn the dial a small amount, you receive a small increase in brightness. The dimmer switch is sending thin pulses of electricity to the light, turning it on and off so rapidly that it appears to be constantly on. The key to PWM is the pulses of current, which reduces the total amount of electricity the light uses when compared to a traditional light that receives a constant or direct current.

When the dimmer switch is turned up to increase brightness, the switch sends thicker pulses of electricity to produce more light. Our motors will use more power at higher speeds because of the direct current that is constantly sent when compared to a PWM, which increases efficiency by sending pulses of electricity. When looking at trolling motors, thin pulses of current will create slower speeds while thick pulses of current will create faster speeds. However, it should be noted that when using a PWM at higher speeds, you lose efficiency and the benefits of the PWM device since the space between pulses becomes smaller. A PWM will result in longer battery life at lower speeds and will allow you to use a dial to choose your exact speed. See the video below for an additional explanation.

2. What do you need to buy to set up a PWM?

Newport does not sell PWMs, however, they can be purchased on Amazon for $20-$50.

Installing a PWM will require additional marine-grade wire and five heat shrink kit wire connectors to attach to the four screw terminals on the PWM device. The fifth is used for the positive wire that attaches from the PWM to the circuit breaker. It is important to use marine-grade wire that is tin-coated to prevent oxidation, which can cause efficiency issues. #10 AWG is required for 36lb to 55lb thrust motors, while #8 AWG is used for 62lb and 86lb thrust motors. While there are other options for attaching the connectors to the PWM, we highly recommend a wire shrink kit as mentioned earlier. More on this later.

3.What features do I need and how to choose?

Many kayakers like to purchase PWMs that feature a digital readout with a forward, reverse, and off switch. The digital readout shows the current percentage of speed out of the total potential speed, making trolling motor operation with the PWM much easier.

When choosing a PWM you need to match the Voltage and Amperage that your trolling motor is rated for. Our 36LB-62LB motors (any series) operate on a 12V system, which requires a 12V rated PWM. Our 86lb thrust motor (any series) uses 24V for operation and would require a 24V rated PWM. For amperage rating, we recommend choosing a PWM that is rated 10A greater than the circuit breaker that came with your motor. For our example, the 36LB Kayak Trolling Motor has a 40amp circuit breaker, so the PWM should have a rating of 50amps. You can view “Tech Specs” on our product pages for this information. This will put less strain on the PWM in the event you are using the motor at top speed most of the time. With the circuit breaker securely connected, this will help ensure to protect both your PWM and trolling motor.

4. How to Wire?

Each PWM will have slightly different sized screw terminals, which can be tricky to attach your marine-grade wire to. We recommend a marine-grade wire shrink kit that can be purchased for $12-20. Ensuring that both the shrink kit and the wires are marine-grade will help increase the longevity as well as the strength of these connections. It is beneficial to buy a kit with different types of male wire connectors to allow a secure connection to the PWM female screw connection. For instructions on how to put an adapter on the end of a wire, see the video below.

Benefits of Using a Wire Quick Disconnect Attachment

We realize many boat owners like to use quick disconnects for their ease of use. This is perfectly acceptable and you will simplify the connection process to your PWM. However, quick disconnects can lead to voltage drop and less efficient power transfer. To accomplish this, match the gauge of the wire on your trolling motor to the gauge of the quick disconnect. When purchasing, make sure you get 2 pairs of quick disconnects (2 x Male & Female ends). Reference the YouTube video below for an example of PWM set up using quick connectors. Important note: It is recommended to use the provided circuit breaker with your trolling motor because of the possibility of a PWM failing or shorting power. USCG law states operators must place the circuit breaker within 7 inches of the source of power.

5. How to store/protect your PWM device?

There are a few methods to protect your PWM device. Many people purchase a plastic container that has a rubber seal to protect the PWM from water. Another option is placing the PWM on a stand (like this) inside the box to improve cooling. Please see the YouTube video above for an example. Some kayakers will drill holes to allow airflow. An example can be found on Josh Koch’s YouTube Channel. Please note that the PWM can generate heat and any damage to the motor from the PWM device will not be covered by our warranty.

6. How to install a PWM device?

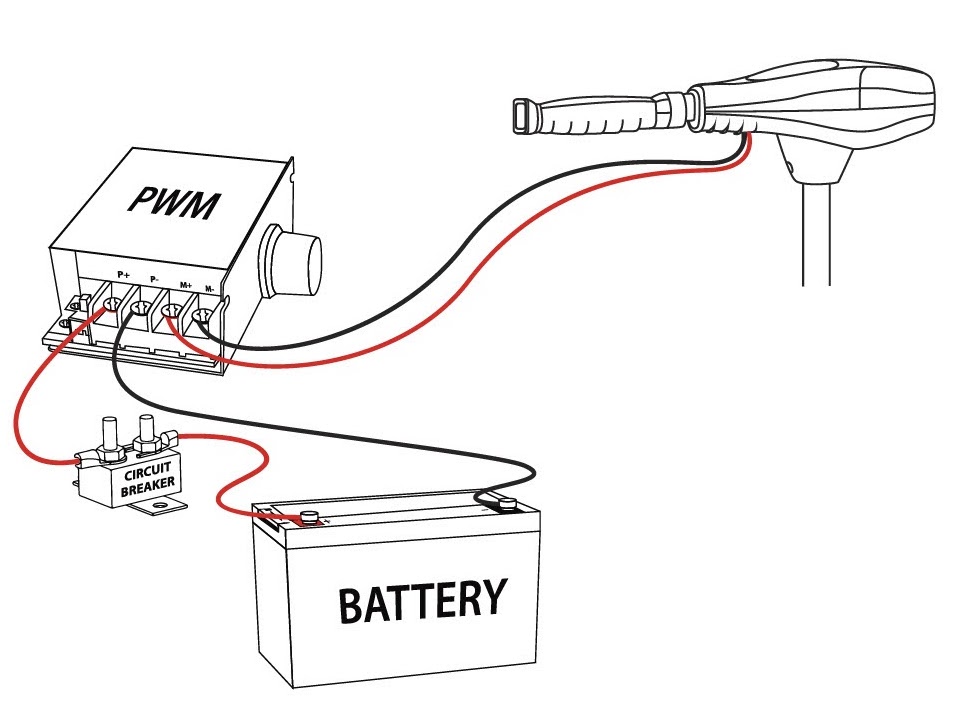

- Identify the trolling motors' positive and negative wires and attach them to the terminals labeled ‘Motor +/-’ on the PWM.

- Note many PWMs terminals are very small. You may want to purchase a marine-grade shrink kit ($12-20), strip the ends of the wires, and install new ends onto the trolling motor wires so they can fit on the PWM’s terminals.

- Take the extra marine-grade wire you purchased and attach it to the terminals marked “Battery/Power +/-” on the PWM.

- Take the positive (red) wire coming off of the PWM and attach it to the silver terminal of the circuit breaker.

- Attach the wire extending off the circuit breaker to the positive (red) terminal of the battery.

- Attach the negative (black) wire from the PWM directly to the negative terminal of the battery.

7. How to turn on a PWM device?

Once your PWM is installed, have the PWM device switch in the off position. Turn the motor handle to the highest forward speed, speed 5. This will allow the motor to accept full power without limiting any of the current. Then you can turn your PWM on and control the motor with the PWM dial.

8. How to change between forward and reverse?

Many PWM devices will come stock with a switch that allows you to change the polarity (reverse/forward) from the device itself. This allows you to use the motor in reverse by turning the dial for the speed to off, hitting the switch from forward to reverse, and then choosing your speed with the attached dial. If a PWM device does not have this function, you will have to manually turn the trolling motor handle to reverse speed 3. It is important to allow the propeller to stop spinning completely before changing between forward and reverse speeds. Improperly using a PWM can damage the trolling motor and result in voiding the warranty.

A PWM cannot control the direction of travel, only the speed. Newport currently doesn’t offer any kits for remote-control steering. For remote steering, customers will have to check out other sources. Using a PWM will not void your warranty if you use it with our supplied circuit breaker, but the user must ensure the PWM matches your motor’s ratings. For more information on our motors see our Motor Support Page here to our support page.

If you can’t find the information you need give us a call (866) 721-0002 Monday to Friday: 8:30 am - 4:30 pm or reach out to us via email at SUPPORT@NEWPORTVESSELS.COM.